TRANSFORM YOUR AIR/FAN SYSTEMS INTO BIOAEROSOL

“KILL on the FLY” Fighting Machines up to 99% / 1 ST PASS INACTIVATION RATES

It’s well documented that Coronaviruses are 3x more suspectable to germicidal UV c-band light (radiation) than other viruses such as Influenza A. See table.

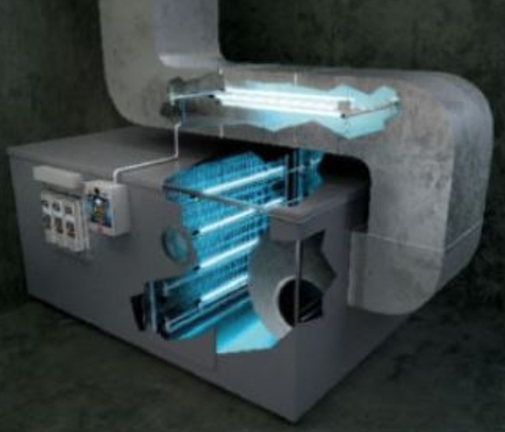

EMA can quickly design a custom germicidal lamp retrofit system using high-output UV-C lamp technology to transform your fan system into a SARS-corona killing machine with 99% 1st pass kill rates.

OPEN LETTER

Special message from Steve Di Giacomo, Principal Engineer and CEO:

Greetings to all, in these unprecedented times.

I have good news and bad news.

The bad news is another significant spike in SARS Corona is expected this Fall, and according to a number of sources including a JAMA article published in April 2020, SARS-CoV-2 airborne transmission occurs during normal breathing let alone coughing, and sneezing. The transmission vectors are fomite, droplet, and airborne, where EMA’s retrofit designs address airborne transmission of several key bio-aerosols.

Now for the really good news. SARS coronavirus is one of the easier viruses to inactive (“kill”) with UV germicidal lamps; in fact, it is 3x easier to inactivate than influenza A (flu), and we can do so cost effectively with benefits that include reduced absenteeism, higher worker productivity, and chiller plant air-conditioning energy savings for as little as 40 cents a CFM.

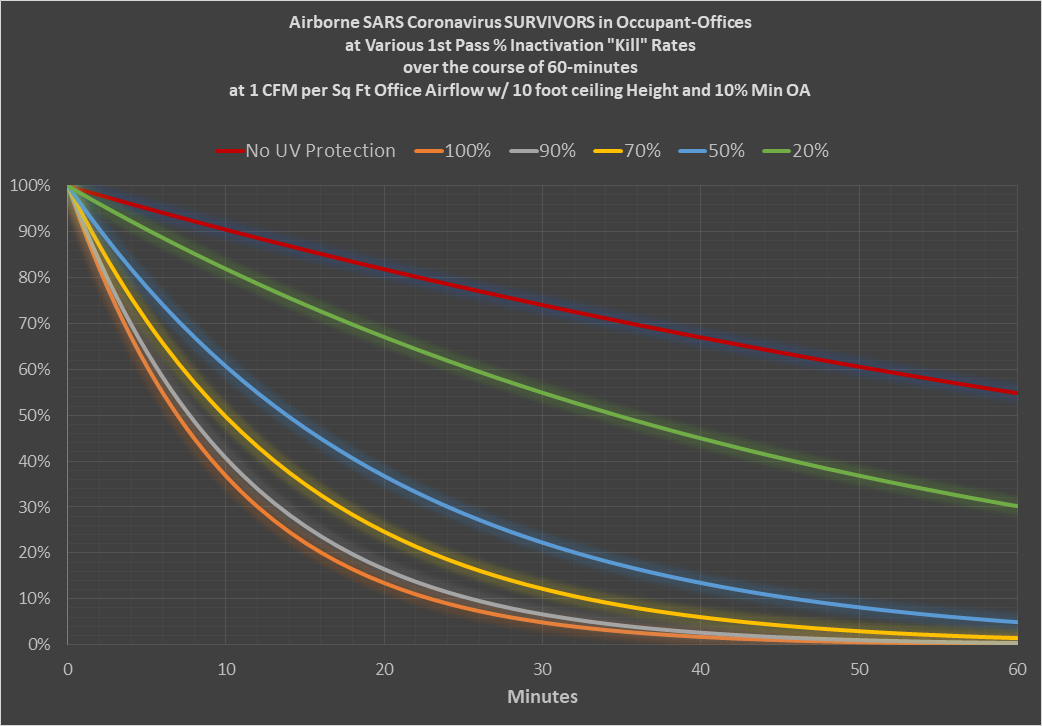

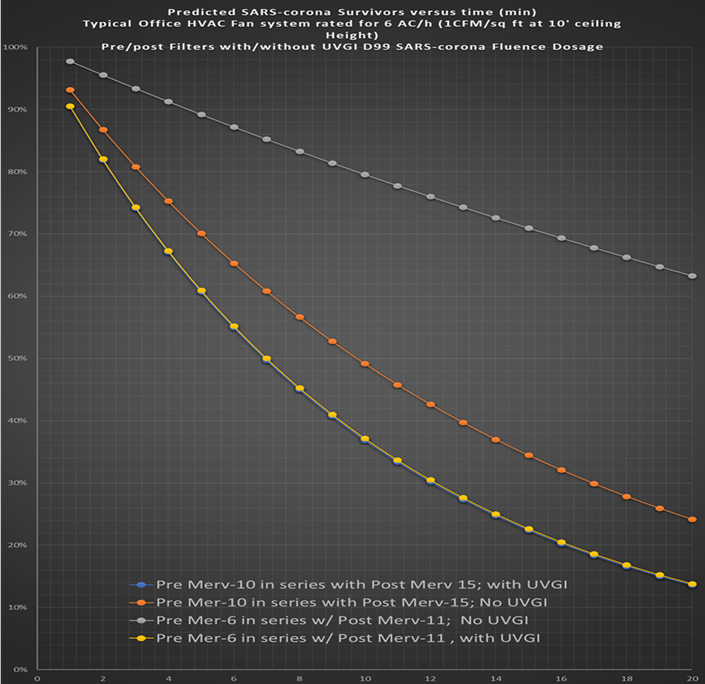

EMA’s HVAC air-handler retrofit designs target 1st Pass “Kill” rates of 95% under worst-case conditions leading to Tenant Zone occupant dissipation rates of 95% for SARS & Tuberculosis (TB) in 30-minutes and 99.8% dissipation rates in 60-minutes. See Chart A.

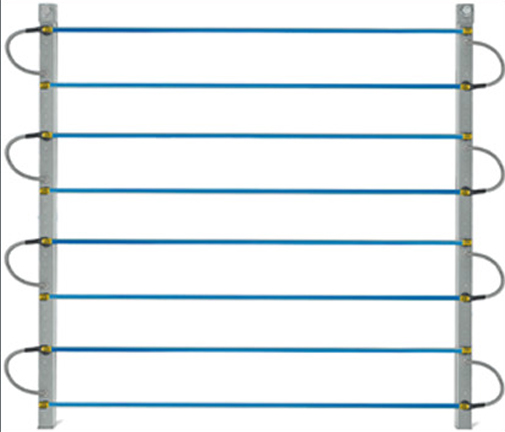

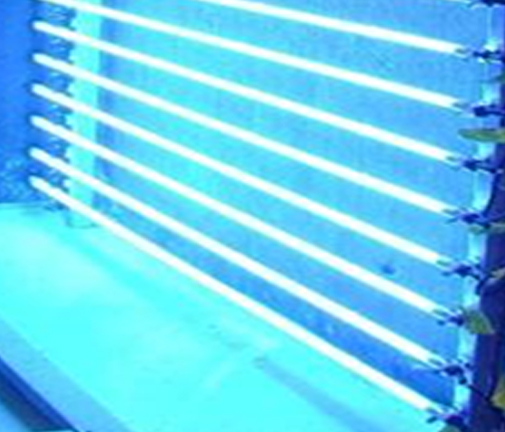

We accomplish this by designing ultraviolet lamp-retrofits of your existing air-handlers and roof top units with 253.7 nm (2537 Å) wavelength germicidal ultraviolet lamp systems that emit zero ozone; these high out (HO) low pressure Hg vapor lamps are protected with EncapsuLamp™ technology for enhanced safety and increased performance.

- Engineering fees are just 1k to $3k per building.

- Turnkey costs range from $0.50 to $0.55 per square foot of conditioned space.

Health Benefits of UVGI Lamp Systems in Retrofitted AHUs/RTUs

EMA’s air-handler retrofit designs are creating a healthier built environment leading to increased worker productivity and/or decreased absenteeism by inactivating highly infectious bio-aerosols in 0.25 to 0.75 seconds “On the Fly” with 1st Pass Kill rates of 98% for SARS-corona at 50% rh, 99% for Tuberculosis at 50% rh and 70% for Influenza-A at 50% rh.

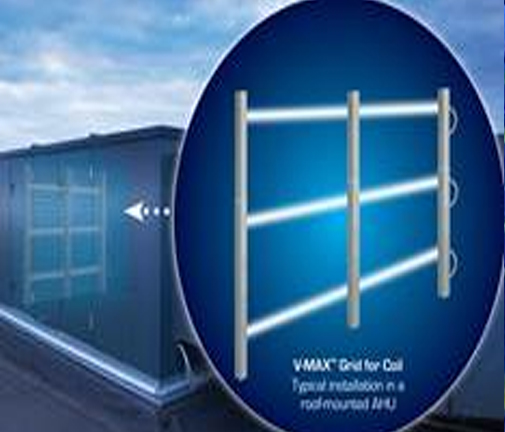

Deploying this technology inside of existing air-handlers and rooftop units prevents “return-air bioaerosols” from being re-distributed throughout the building via your supply air plenum ductwork.

Our retrofit designs Increase occupant zone-level effective Air-exchange rates from 0.6 AC per hour to 6 effective AC per hour resulting in 95% dissipation of SARS and T.B. from your tenant’s space in 30 minutes and 99.8% dissipation in 60-minutes. See Chart A .

Chart A

Areas of High Congregation

Conference rooms, lobbies, workout rooms and reception areas can be supplemented with upper room U.V. wall packs that can be typically mounted at 7 ft. to 8.5 ft wall height. Typically, these wall packs lead to 8 to 18 effective air-exchanges per hour, and a recent JAMA article (April 2020) places that figure at 24 effective air-changes per hour. Visit our News & Resource Center to download your copy.

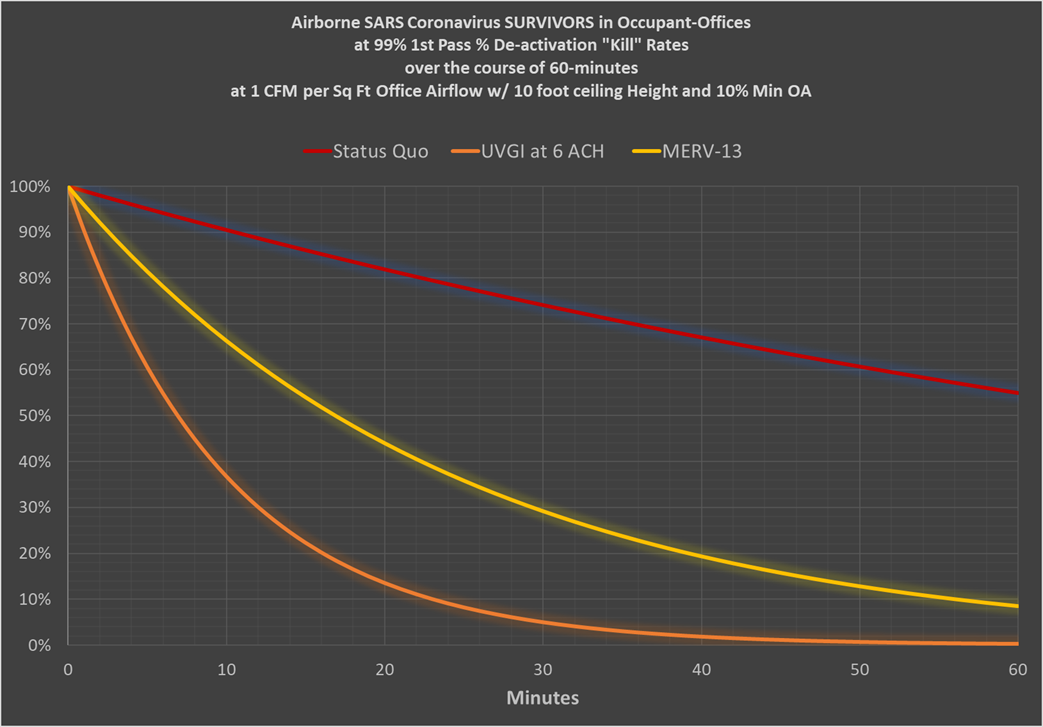

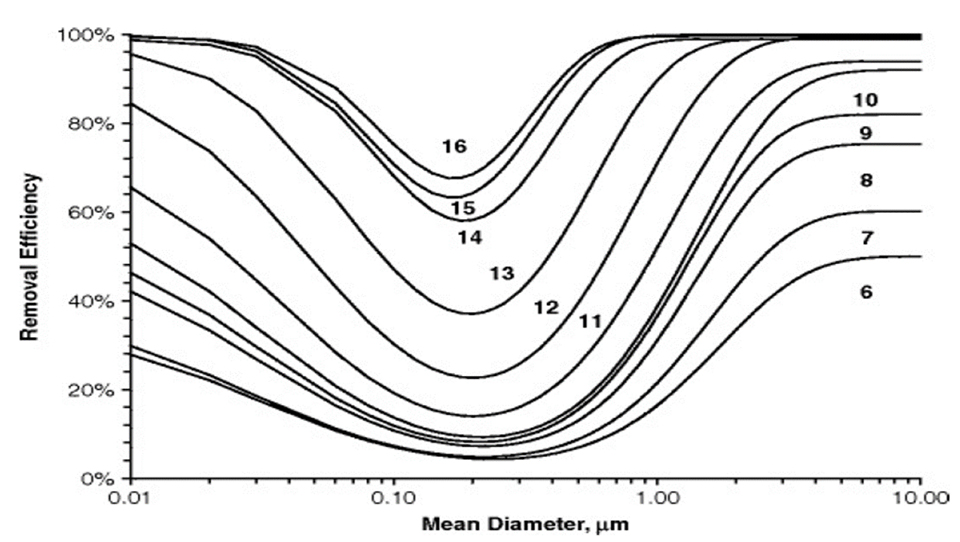

- Eliminates the need to increase MERV filter ratings as recommended by ASHRAE PD1. See Chart B, below.

- Eliminates the need to increase OA Mins as recommended by ASHRAE PD.

- Eliminates the need to bypass and shut-off your ERV energy-recovery-ventilator enthalpy wheel as recommended by ASHRAE PD to mitigate the wheel’s inherent 2% cross-contamination. By not bypassing your wheel the ERV will continue to function as designed, saving 50% to 70% of your system’s energy.

- Eliminates DX/CHW coil power washings because UV light inactivates and breaks down biologicals that clogs coils, increase pressure drops, increase fan motor energy and decreasing heat exchanger efficiency causing most chiller plants to use more energy.

- Eliminates the need to disable DCV (demand-controlled ventilation) as recommended by ASHRAE PD which in large single zone areas such as gyms, auditoriums, and classrooms with large %OA components.

- Eliminates the need to increase zone relative humidity to 40% - 60% as recommended by ASHRAE PD; increasing RH promotes mold/mildew when RH exceeds 50%.

- Causes your 0.6 air-exchange rate office HVAC system to behave like a once through system, such as a DOAS system or 100% OA lab systems with 6 air-exchanges per hour, but without the huge energy penalty.

1 ASHRAE PD is available in our NEWS & RESOURCE CENTER

- Send us an email at steve@ema-boston.com with your contact info and convenient time to talk.

- EMA will arrange a site visit with one of our specially trained engineers to take field measurements, gather data on your systems and controls, and determine lamp system location options.

- On a system by system basis EMA will determine the required UV lamp arrays and power distribution requirements necessary to deliver a D95 (95%) Kill dose at design HVAC conditions taking into account your system’s air-velocity, air temperature, plenum cross-sectional area, plenum length (run), exposure time, reflectivity of the coil and plenum surfaces, lamp “wind chill”, lamp UV efficiency, lamp end-of-life degradation, and inverse square law fluence contributions.

- EMA will calculate required UV power required to deliver the proper Kill Dose, then we will share this info with experienced UVC vendors. Once EMA receives their proposals, we will determine final calculated delivered Dosages under worst case design conditions, and pass all info onto your review.

- Together we will determine next steps. Below is a typical 1st Pass Kill rate table based on EMA’s calculated Dosages under worst case (design) conditions. These can be considered minimum “kills” with higher inactivation rates occurring on non-peak days.

Table-1

| Location | SARS-corona 1st Pass Kill at 50% RH Air | Tuberculosis 1st Pass Kill at 50% RH Air | Influenza A 1st Pass Kill at 50% RH Air |

|---|---|---|---|

| AHU-1 | 97.9% | 99.2% | 70.5% |

| AHU-2 | 99.0% | 99.7% | 76.6% |

| AHU-3 | 99.3% | 99.8 | 78.7% |

Table-2

| Virus | Type | % RH | Virus Diameter | Airborne De-activation Factor (k) | U.V. Dose required 99% Kill / Inactivation |

|---|---|---|---|---|---|

| Coronavirus (incl. SARS) | ssRNA | 50% | 0.125 µm | 0.00377 cm2/µWatt sec | 1225 µWatts sec/cm 2 |

| Mycobacterium Tuberculosis | ssRNA | 50% | 0.35 µm width x 3 µm length | 0.004721 cm2/µWatt-sec | 980 µWatts sec/cm2 |

| Influenza A | ssRNA | 68% | 0.098 µm | 0.00119cm2/µWatt-sec | 3870 µWatt sec/cm2 |

History of 1st Pass “On-the-Fly” Kills

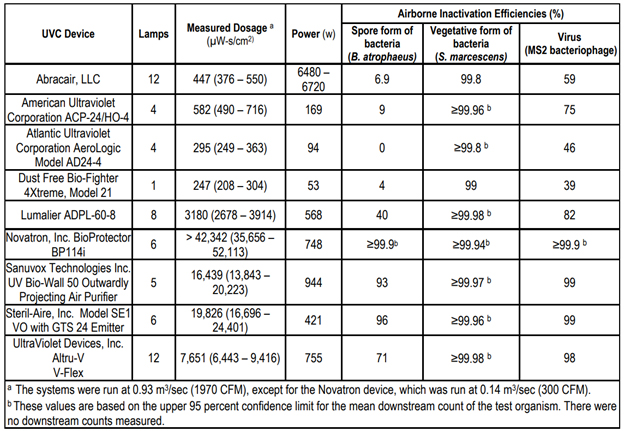

EPA / Homeland Security funded nine (9) studies that documented HVAC In-Duct 1 st Pass Inactivation rates, using UVGI (UVC) at 253.7 nm (2537 Å), as high as 99.98% (almost a 4-log kill) for organisms (spores/bacteria) that are much more difficult to inactivate than SARS-corona.

Below are tabled results, a link to the 9-study summary, and individual links to each study.

Summary Link: Biological Inactivation Efficiency of HVAC In-Duct Ultraviolet Light Devices

U.S. Department of Homeland Security – 9 Case Studies

These bacteria are much harder to kill than SARS-corona based on their UVGI inactivation rate constants.

EPA / U.S. DHS links to individual URLs/Downloads for the above studies. Test Results are found on either page-11 or 12 of each study.

- BIOLOGICAL INACTIVATION EFFICIENCY BY HVAC IN-DUCT ULTRAVIOLET LIGHT SYSTEMS ABRACAIR, LLCIN-DUCT SYSTEM (1ST PUBLISHED REPORT)

- Technology Evaluation Report American Ultraviolet Corporation Acp-24/HO-4 Biological Inactivation Efficiency (2ND PUBLISHED REPORT)

- Technology Evaluation Report Atlantic Ultraviolet Corporation Aerologic Model AD24-4 Biological Inactivation Efficiency by HVAC In-Duct Ultraviolet Light Systems (3RD PUBLISHED REPORT)

- Technology Evaluation Report Dust Free Bio-Fighter 4 XTREME, MODEL 21 Biological Inactivation Efficiency by HVAC In-Duct Ultraviolet Light Systems (4TH PUBLISHED REPORT)

- TECHNOLOGY EVALUATION REPORT LUMALIER ADPL-60-8 BIOLOGICAL INACTIVATION EFFICIENCY BY HVAC IN-DUCT ULTRAVIOLET LIGHT SYSTEMS (5TH PUBLISHED REPORT)

- Biological Inactivation Efficiency by Hvac In-Duct Ultraviolet Light Systems, Novatron, Inc., Bioprotector (6TH PUBLISHED REPORT)

- Biological Inactivation Efficiency By Hvac In-Duct Ultraviolet Light Systems-Sanuvox Technologies Inc. Bio-Wall Outwardly Projecting Air Purifier (7TH LISTED PUBLISHED REPORT)

- Biological Inactivation Efficiency by HVAC In-Duct Ultraviolet Light Systems-Steril-Aire, Inc. Model SE 1 VO with GTS 24 VO Emitter (8TH PUBLISHED REPORT)

- Biological Inactivation Efficiency By Hvac In-Duct Ultraviolet Light Systems- Ultraviolet Devices, Inc. V V-Flex (9TH PUBLISHED REPORT)

In all nine studies the 1st Pass Kill rates ranged from 99%-99.98% (nearly a 4-Log Kill) for Serratia marcescens (Vegetable bacteria). Again, please note that these bacteria are much harder to inactivate than SARS-corona based on their UVGI inactivation rate constants.

These studies suggest that achieving 99.9% (3 log) 1 st Pass inactivation (kill rate) in airstreams for SARS-corona with UVC at 253.7 nm (2537 Å) is possible when the engineering is carefully performed using dosage modeling software and/or dosing charts.

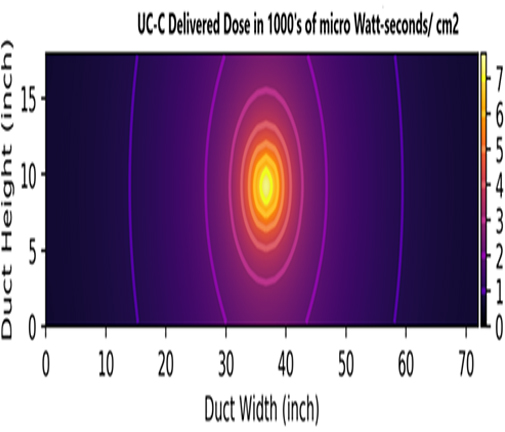

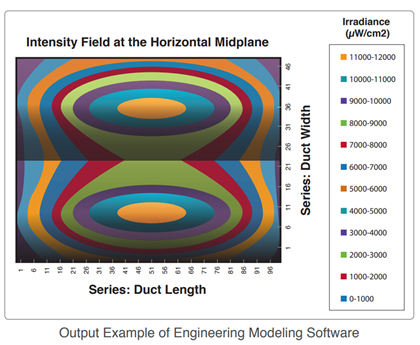

UVGI Dosage-intensity modeling output

Of great importance in the work that we are doing is proper documentation of the SARS-corona virus UVGI k-factor reported as 0.377 m2/J or

0.377 uW/cm2 or 0.00377 cm2/µW-sec at 50% rh which are the 3 commonly used systems of measure. Attached is just one of many studies that document that U.V. k-factor for 253.7 nm wavelength irradiance (which is the output frequency of most UVC low pressure Hg vapor lamps).

In this paper the “k” factor is called the “Z” factor.

The 99% 1st Pass Inactivation Dose (D99), leaving 1% Survivors is determined by direct calculation as follows.

D99 = Natural Log (1-0.99) / (-k) = -4.6052 / -0.00377 cm2 / µW-sec = 1222 µW-sec / cm 2

Once the kill rate and subsequent desired delivery Dose (light fluence) is finalized and exposure time is field-determined, EMA sets out to design a lamp array system to deliver the necessary UVGI Intensities (light fluence) in the allotted exposure time. EMA then develops custom Inactivation (Kill) Rates to your building’s air-handlers systems, similar to Table-1, above for SARS-Corona, Tuberculosis and Influence A.

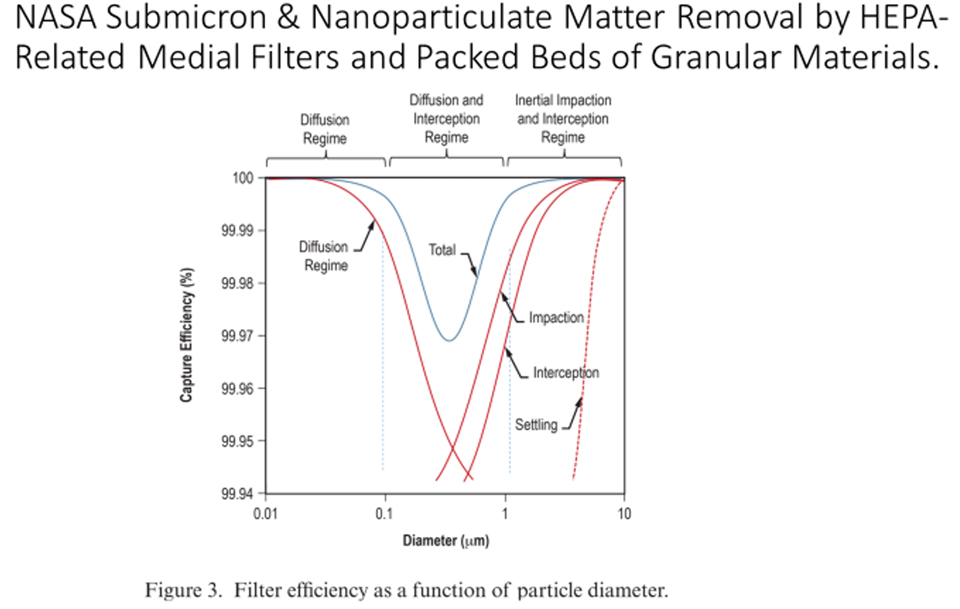

A Quick Word on Increasing MERV air-filter ratings in lieu of UVC lamp fan retrofits

UVGI lamp systems should be the first line of defense against SARS-corona. If you have limited funds and must choose between (A) increasing MERV air-filter ratings or (B) retrofitting with UVGI lamps systems for a 99% (D99 fluence) 1st Pass deactivation (Kill) rate, you should install UVGI. If you have funds to complete both projects then do so because a higher MERV rating will maintain cleaner UVGI lamps, further reducing (slightly) the number of Survivors.

Below is our analysis that demonstrates that whether you have low MERV pre/post filters or higher 10/15 (pre/post) MERVs, matters not, as long as you retrofit with UVGI lamp system designed for 99% 1 st pass deactivation. This chart assumes we are retrofitting a standard RA office air-handler, delivering 1 CFM / sq ft airflows with ceiling height of 10’ (max. 6 “effective” air-changes per hour, based on total air).

HEPA filters would not provide same level of inactivation as UVGI, and HEPA would require a huge capital outlay for a new racking system, and motor upsizing, not to mention a permanent increase in annual electric and filter replacement costs.

Notice the blue and yellow curves are almost indistinguishable, demonstrating that increasing existing MERV filter ratings cannot outperform UVGI.

Chart B

DISCLAIMER

UVGI is scientifically proven to deactivate viruses and bacteria in air, water and on surfaces. UVGI upper room wall packs, air-handler and plenum Lamp retrofit strategies are recommended by ASHRAE. However, there are a large number of factors that control and affect infection rates within buildings, therefore, there are no explicit or implicit guarantees or warranties that adopting and deploying UVGI technology will eliminate or significantly reduce infection rates or disease transmission rates within your building. Other factors that affect infection rates and disease transmission include, but is not limited to, zone temperature, zone relative humidity, ventilation effectiveness, zone pressurization, occupant densities, occupant densities of diseased occupants, air filtration, etc. EMA shall not be liable for or bound in any manner by, and Buyer has not relied upon, any express or implied, oral or written information, warranty, guaranty, promise, statement, inducement or representation pertaining to the subject technology including but not limited to, warranties of fitness or merchantability, regarding or with respect to the subject technology.